Digger undercarriage will be the section of your heavy equipment that a vital role its security and motion.

There are many advantages of utilizing Loonsin digger undercarriage. First, it provides stability towards the machine. Second, the gear is allowed as a result of it to move at a quicker rate, which increases productivity. Third, digger undercarriage reduces the wear and tear of this machine's tires, thus reducing upkeep costs. Last, it improves the flexibility and maneuverability associated with machine, making it safer to navigate through tight areas.

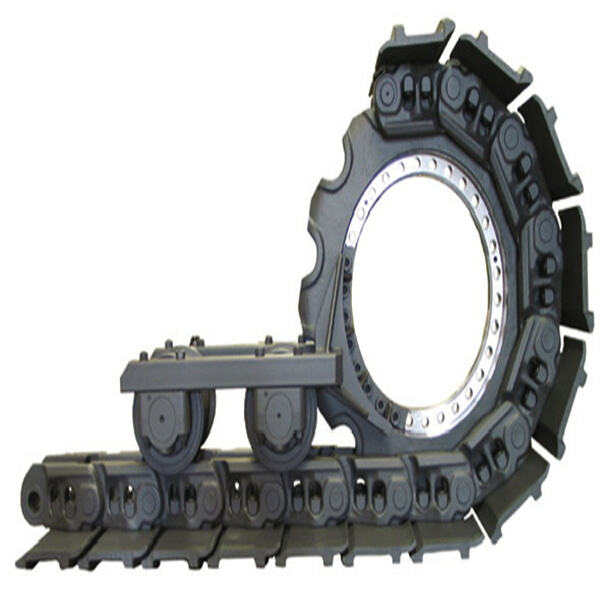

There has been many innovations with Loonsin excavator undercarriage technology. One such innovation the use of plastic tracks. Furthermore, they provide better traction and are less damaging to the pavement. In addition, some manufacturers have developed undercarriage systems that conform to the landscapes to improve stability and minimize wear and tear.

Safety is of more important when operating heavy gear and agricultural machine undercarriage made by Loonsin is not any exclusion. It is critical to stay glued to the maker's recommendations on how to use and keep maintaining the undercarriage. Regular inspections and upkeep schedules can help prevent accidents and prolong the entire life the apparatus. It is important to keep the area around the device clear and to wear appropriate personal equipment is protective.

The device needs to be added to a known level surface to use digger undercarriage. The operator should inspect the digger bucket pin created by Loonsin for any harm and work out certain that the tracks are tight. The unit needs to be started, then even though the operator should accelerate and test the steering and braking system systems.

company vast knowledge manufacturing excavators as well parts bulldozer's chassis. It home 100+ engineers achieved professional digger undercarriage undergoing in-house training. They participated development more 100 different specifications track chains, guide wheels, rollers, bucket teeth, etc. Excavators bulldozer chassis components.

digger undercarriage an area 32291.7313 square feet, 6 large warehouses forging, heat processing intermediate frequency processing precision lathes, all drawings, standardized complete product production line. At same time have variety reliable strategic partners provide various production raw materials.

also offer professional customizations models. factory offers OEM services products similar shelf-digger undercarriage.

factory's products support various extreme environments, including digger undercarriage limited mining operations, saline alkali land operations, frozen environment operations, farming operations, can maintain steady effective work variety hazardous extreme environments.